Engineering data of waste wood boiler houses

- Our solutions ensure efficient utilisation of both wet residuals (sawdust and woodchips of moisture content up to 50%) and dry residuals (sawdust, shavings and wood dust of moisture content up to 30%).

- Modules for heat power generation:

modules up to 5,0 MW for non-dried residuals.

modules up to 2,0 MW for dry residuals; - Boilers and heat exchangers – by leading suppliers.

- Fully automated fuel infeed conveyors

- Requested temperature of hot water pipeline is regulated by automatics, ensuring the temperature regime of the boiler water to be undisturbed.

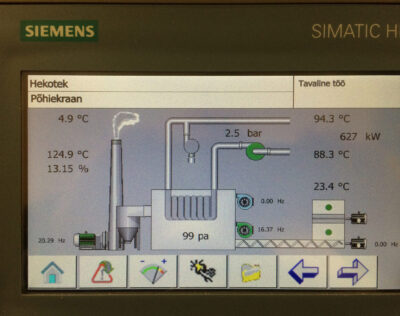

- No need in continuous operator attendance due to fully automatic, visualised control and monitoring system, which allows operating the via computer network.

We offer complex approach and

solutions – from engineering design

and production to daily customer

support.