Engineering data of aspiration systems recirculation

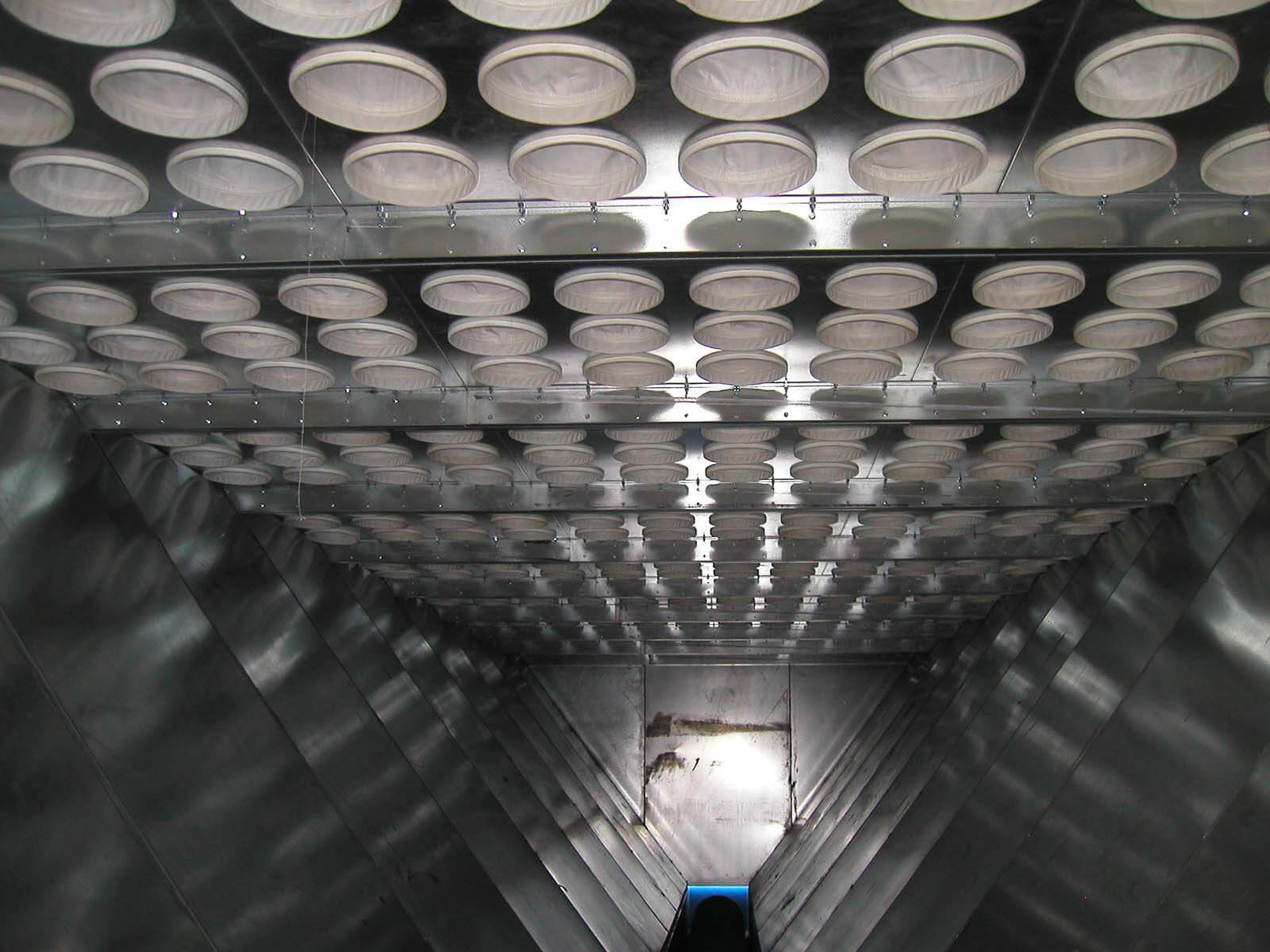

filters

- Filters consisting of standard units for air volume from 10 000 m³/h up to 120 000 m³/h, enable to revert hot air fully or partially back to the production area.

Additional possibilities of filter capacity increase. - Standard filter-bags (217 mm diameter, 2350 mm length). Easy fixation of the bags bottom base by means of spring collar.

- Reverse air channel equipped with fire prevention shutters and reverse air feed regulating valve (summer/winter option).

- Closed-circle solutions for use in dust sensitive areas.

- Pipelines, their ramifications and transitions are designed and produced to transport huge volume of wood waste under minimum energy and air consumption and low level of pressure loss.

Our recirculation filters enable to

optimise your production area

heating costs, as well as to

ensure cleaner operation environment

for your employees.